Energy efficiency takes the lead

ASTA's advanced busbar technology drives Penitas hydroelectric power plant in Mexico

Oed (pts008/25.08.2023/08:30)

Since 1814, Austrian hidden champion ASTA has been a reliable partner in the field of energy generation and transmission, supplying customers worldwide with sophisticated copper technology. During the retrofit of the Penitas hydroelectric power plant in Mexico, ASTA brought its extensive experience to the table, covering the entire supply chain from engineering to the production of ready-to-install busbars.

The Penitas hydroelectric power plant stands as a pivotal endeavor in fortifying Mexico's energy generation sustainably, signifying amplified commitments and investments in the transition to renewable energy sources. Penitas exemplifies Mexico's drive towards sustainable electricity production, showcasing an installed capacity of 420 megawatts divided among four turbines, and an annual output of approximately 2.035 terawatt-hours (TWh). ASTA's main task was to deliver state-of-the-art, energy-efficient busbars that form the core of the rotating part of the generator. These vital components enable the generation of electrical energy and are of paramount importance for the smooth operation of a power plant.

ASTA's facility in Brazil will supply a total of 600 tons of specially insulated busbars until the power plant's completion in November 2023. ASTA won the contract based on its unique insulation technology developed specifically for this project. In addition, ASTA's ability to provide a customized end-to-end solution played a key role in winning the order (tender) from a well-known generator manufacturer.

Dr. Karl Schäcke, CEO of the ASTA Group, stated, "The key factors that set this project apart from others are the specialized manufacturing and processing techniques contrived for this highly demanding application. For the production of the busbars, we have developed a special insulation that ensures the highest performance and safety". He adds, "By modernizing the equipment and using the latest technologies, we and our partners are making a significant contribution to increasing the energy efficiency of the plant and thus to Mexico's energy supply."

Marcelo Porsch, General Manager of ASTA Brazil, emphasizes, "The power conductors developed by ASTA enable the power plant operator to extend the lifespan of these four generators by another 40 years. This not only contributes to sustainable electricity generation at the Penitas hydroelectric power plant, but also embodies a retrofit as a sustainable and resource-efficient solution."

About ASTA Group

The ASTA Group, headquartered in Oed, Austria, has evolved into a globally operating company since its establishment in 1814. With six locations in Austria, Bosnia, Brazil, India, and China, ASTA employs 1,400 employees and is a hidden champion, manufacturing tailor-made copper components for high-performance generators and transformers, the e-mobility sector, and special applications. In the fiscal year 2022, the ASTA Group generated revenues of 480 million euros. With over 200 years of experience and expertise in the production and advancement of precisely insulated flat and round copper wires, as well as special copper components using state-of-the-art manufacturing technologies, ASTA is a trusted partner to leading energy technology manufacturers worldwide, such as Siemens Energy, Hitachi, Andritz AG, and Mitsubishi.

Sustainability is deeply embedded in ASTA's corporate strategy, and the group takes a pioneering role in the industry with its in-house copper recycling capabilities. Since 2022, the company, in collaboration with partners, has been developing a circular copper economy and actively shapes the global energy transition in a resource-efficient, energy-efficient, and ecologically sustainable manner, striving for the best possible ecological footprint.

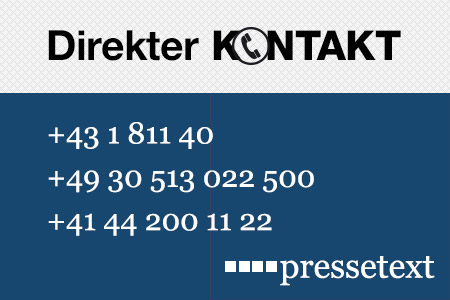

(end)| Aussender: | ASTA Energy Solutions GmbH |

| Ansprechpartner: | Jürgen Beilein |

| Tel.: | +43 664 831 2 841 |

| E-Mail: | offiice@asta.at |

| Website: | www.asta.at |